Using Netfabb Basic to weld shells together.

In this tutorial, I'm going to show how to join two shells together using

Netfab Basic (available for free from www.netfabb.com)

Note: for the specific geometries in this sample, Netfabb is perhaps not the

best tool for the job, but this technique can be used to solve several other

issues as well.

Click any image to zoom.

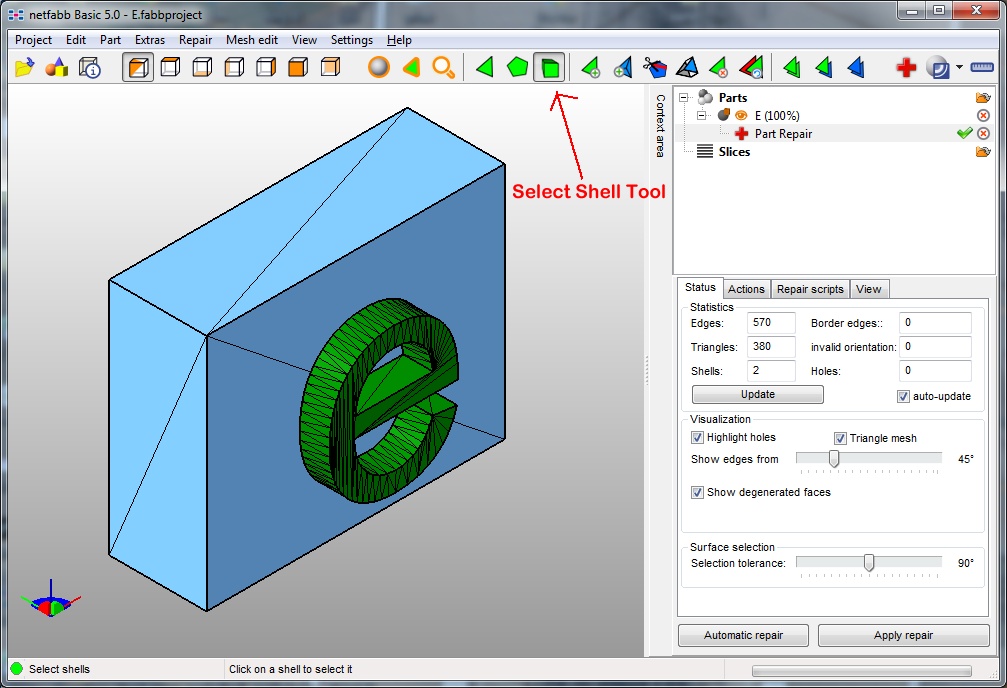

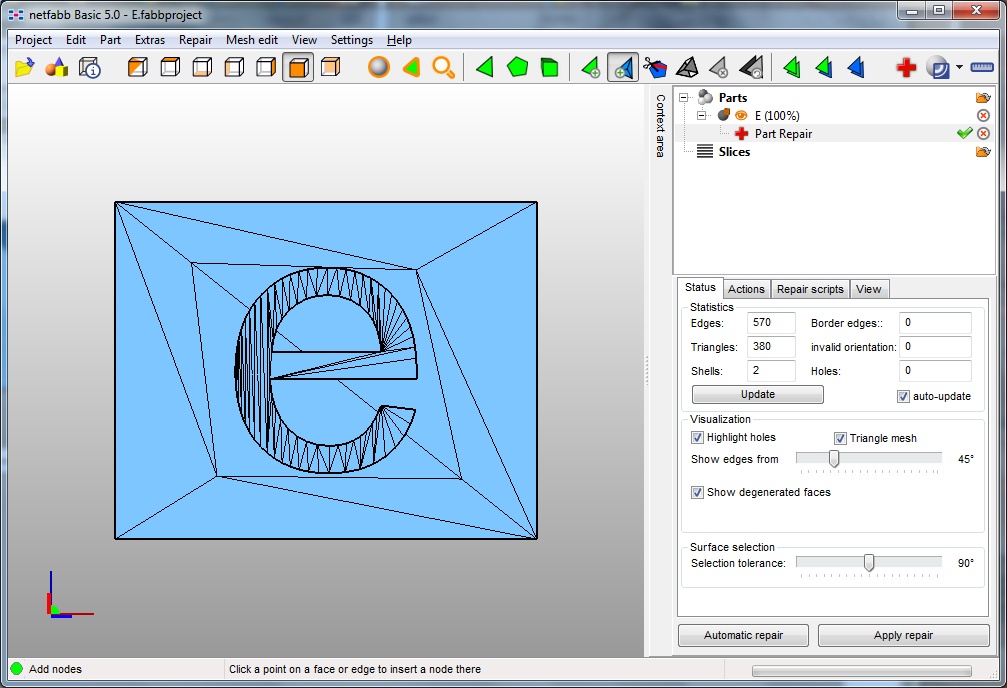

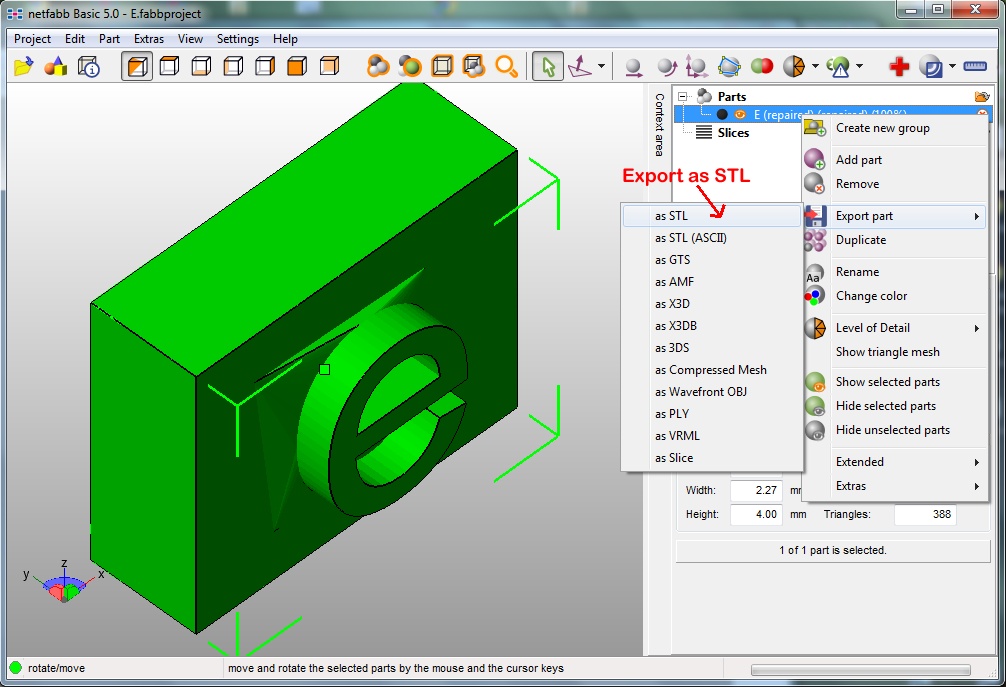

| Step 1 | Load the STL file

into Netfabb. Click the red + sign to start Repair mode.

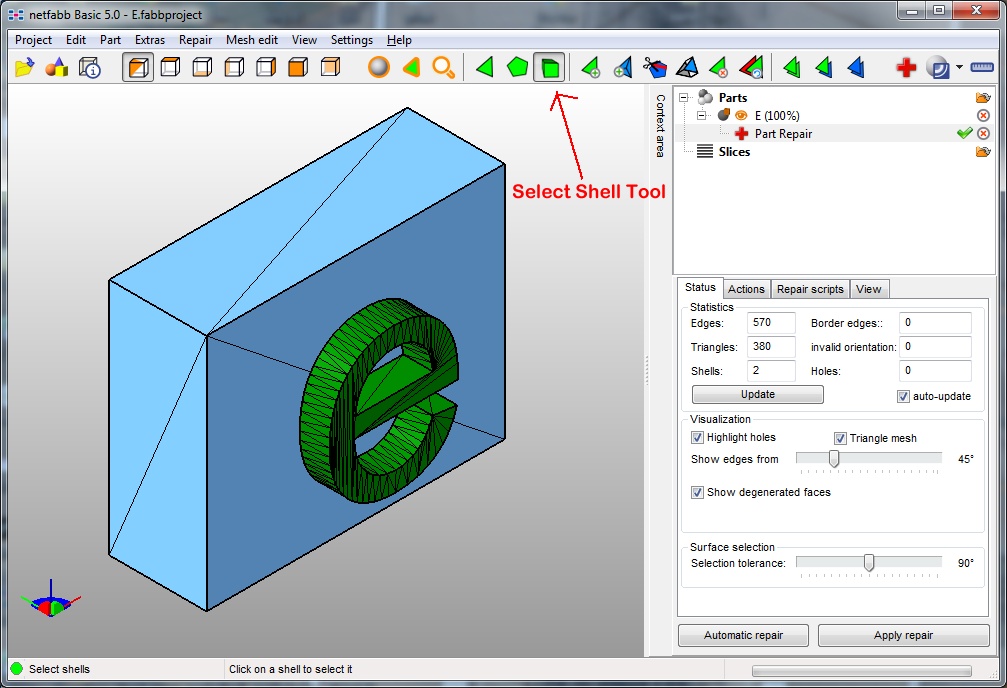

You can then use the Select Shell Tool to explore your model and any

shells that are separate from other shells on the model. Note: it

doesn't hurt to run the STL thru cloud.netfabb.com first so as to

weld together the main body of your model, leaving only the "floating"

shells to worry about. |

|

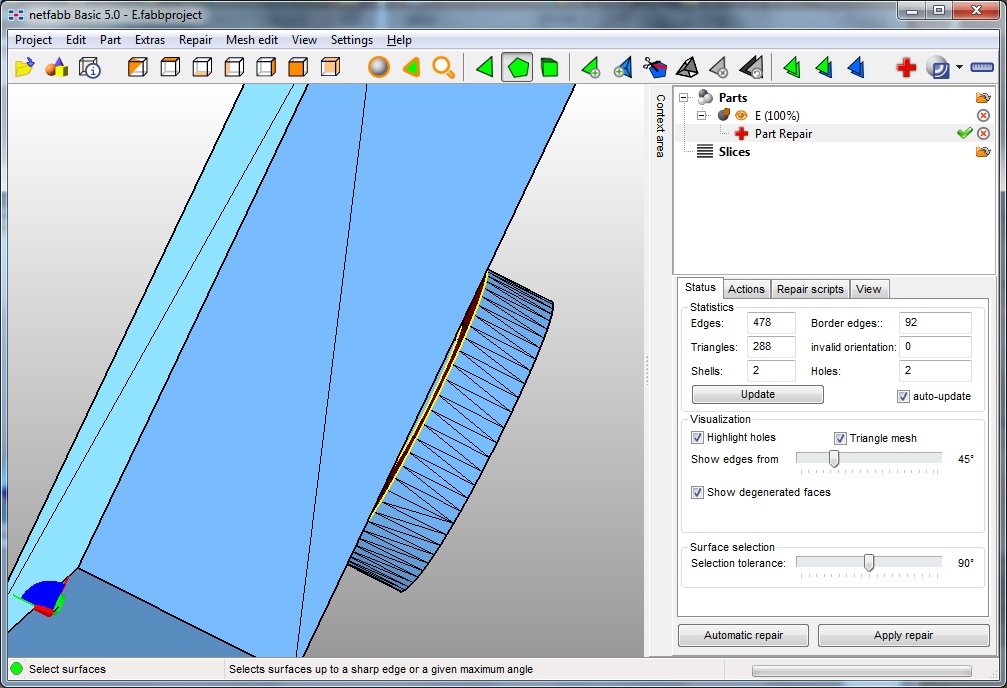

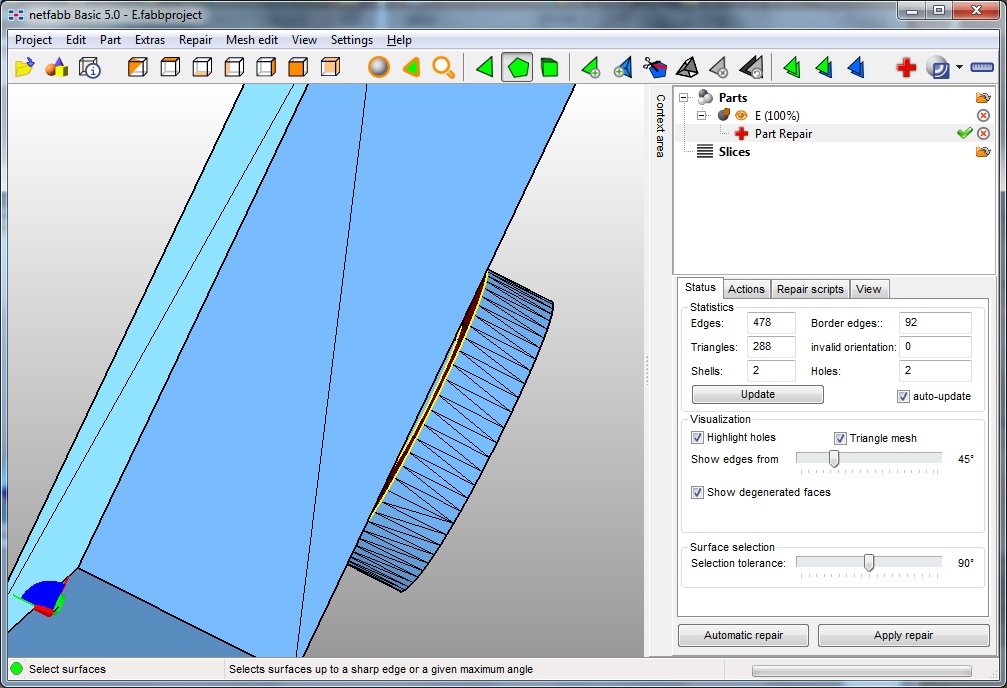

| Step 2 | This model has

two shells that we want to join together. Using Rotate and

Zoom, position yourself so that you can see the back side of letter

"e". Use the "Select Surfaces" tool to select the entire back of

the letter "e"

Then, use the "Delete Triangles" tool to remove the selected

triangles. |

|

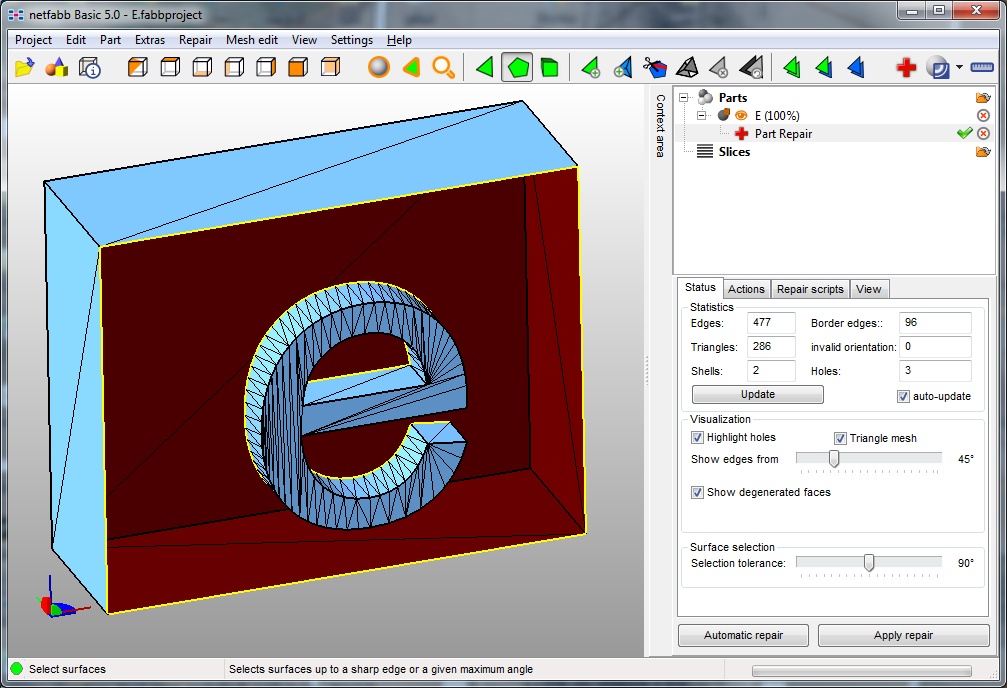

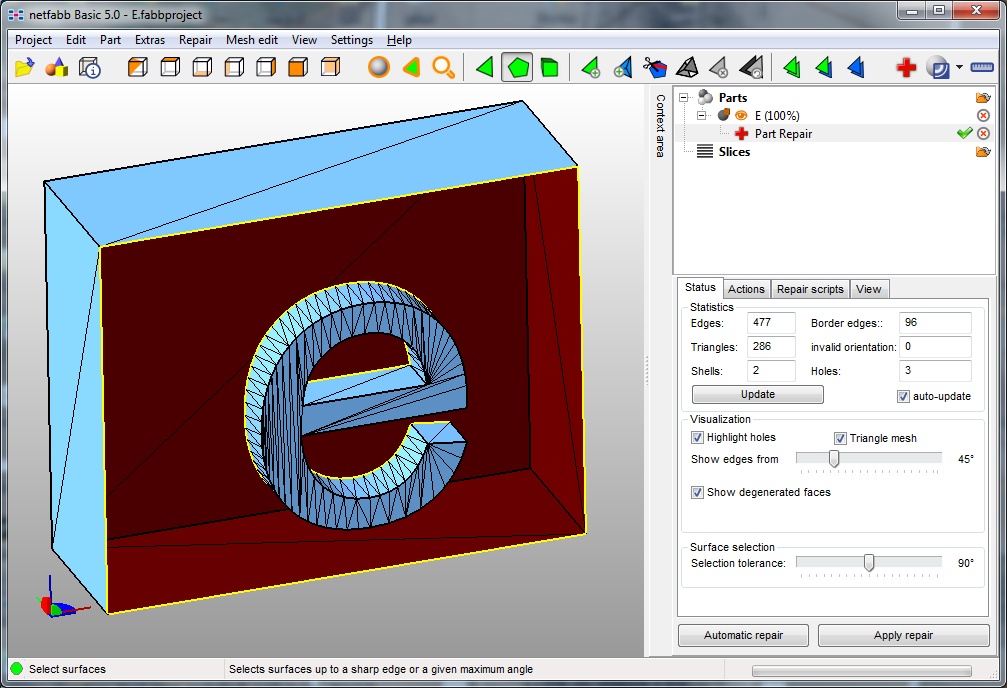

| Step 3 | Here's the model

with the back of the letter "e" removed. |

|

| Step 4 | We could

use the same process to remove the surface that the "e" is supposed

to join to, but as you can see in this case, that would give us a

very large surface to work with - possibly more area than we really

want. |

|

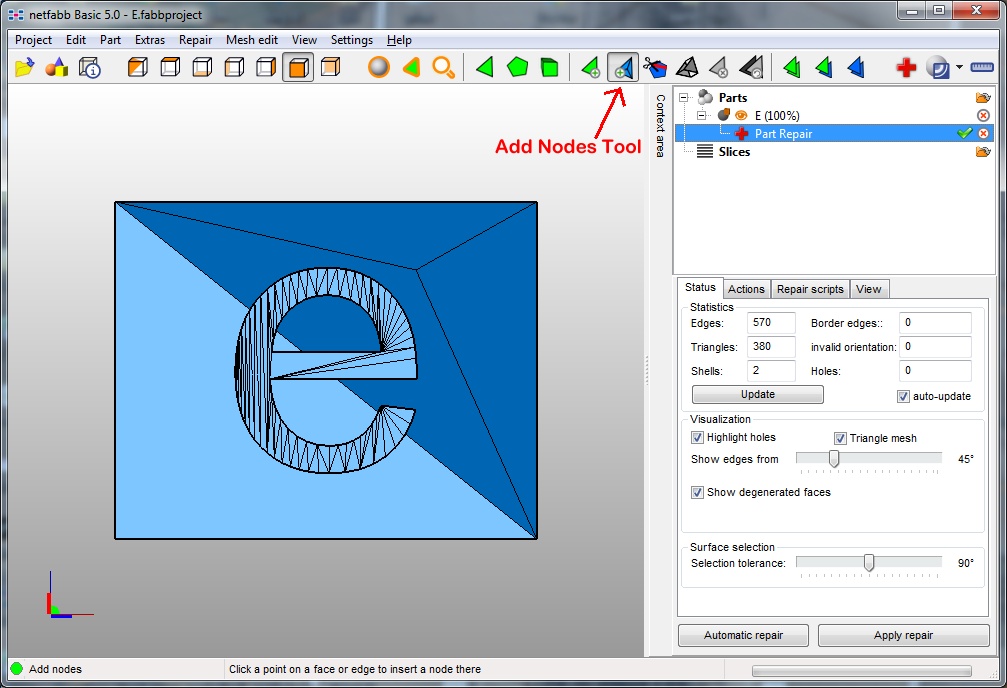

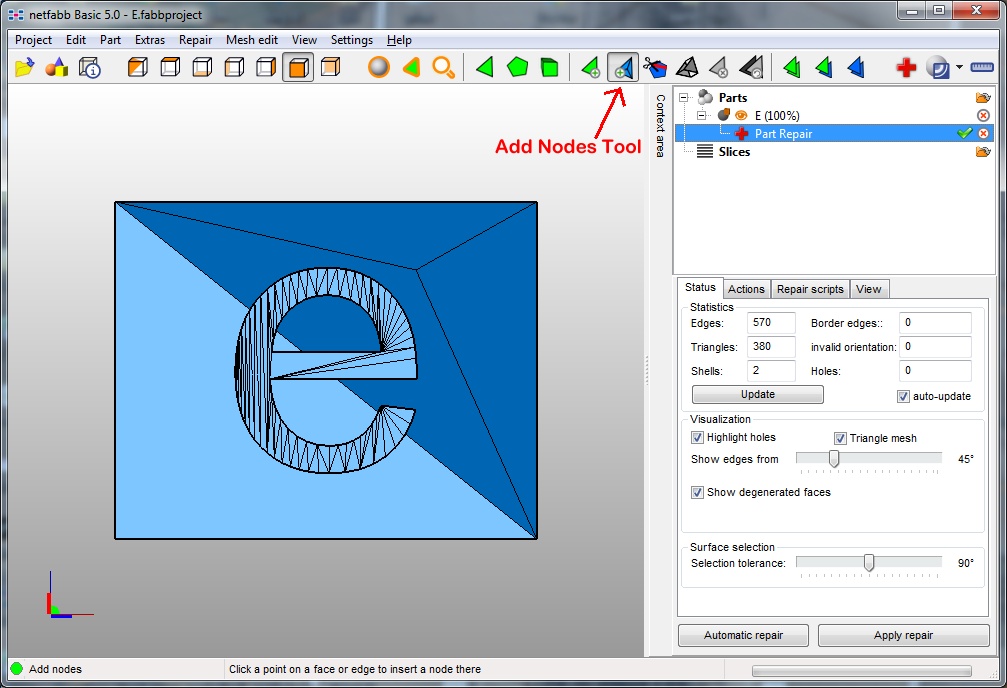

| Step 5 | So, use the "Add

Nodes" tool to add extra nodes to the back wall.. so that we have a

smaller area to work with. |

|

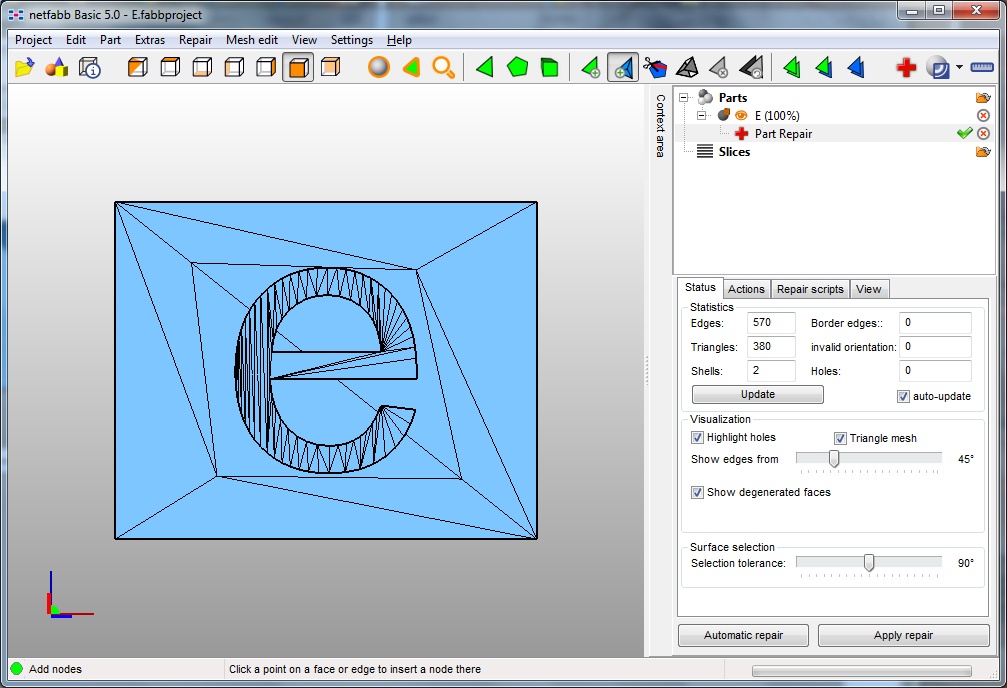

| Step 6 | Adding a few

nodes gives us a smaller region. |

|

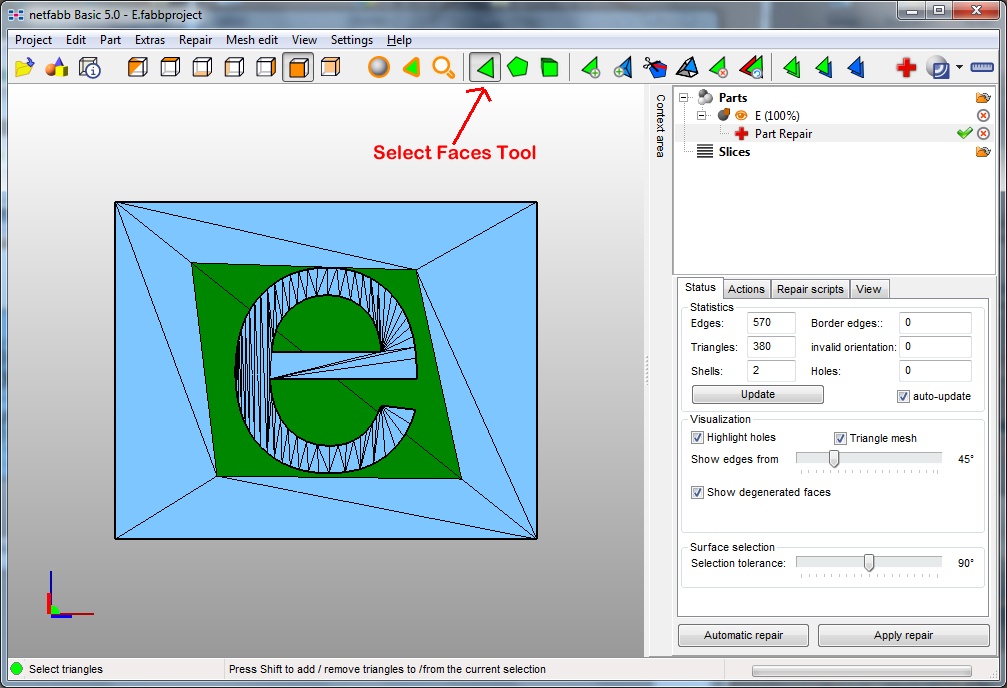

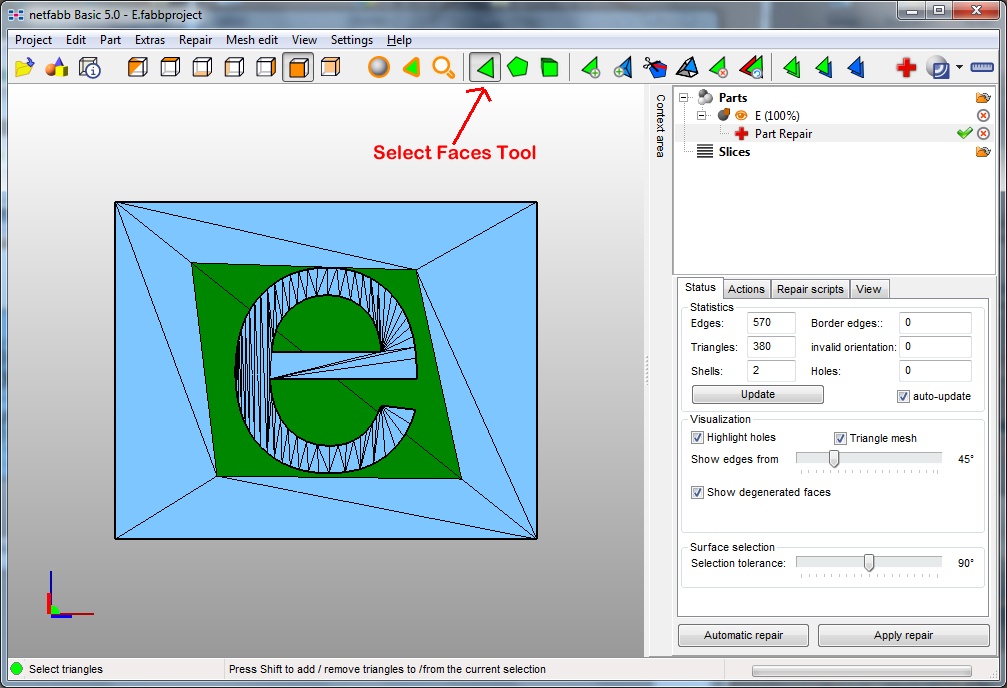

| Step 7 | Now, use the

"Select Faces" tool and remove the triangles directly behind the

letter "e" |

|

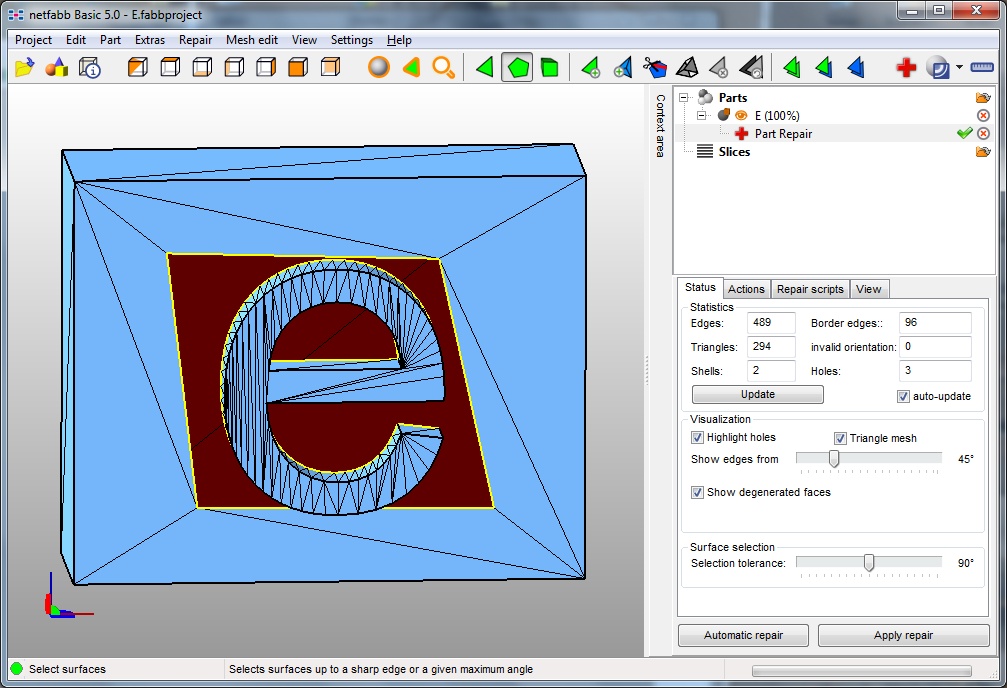

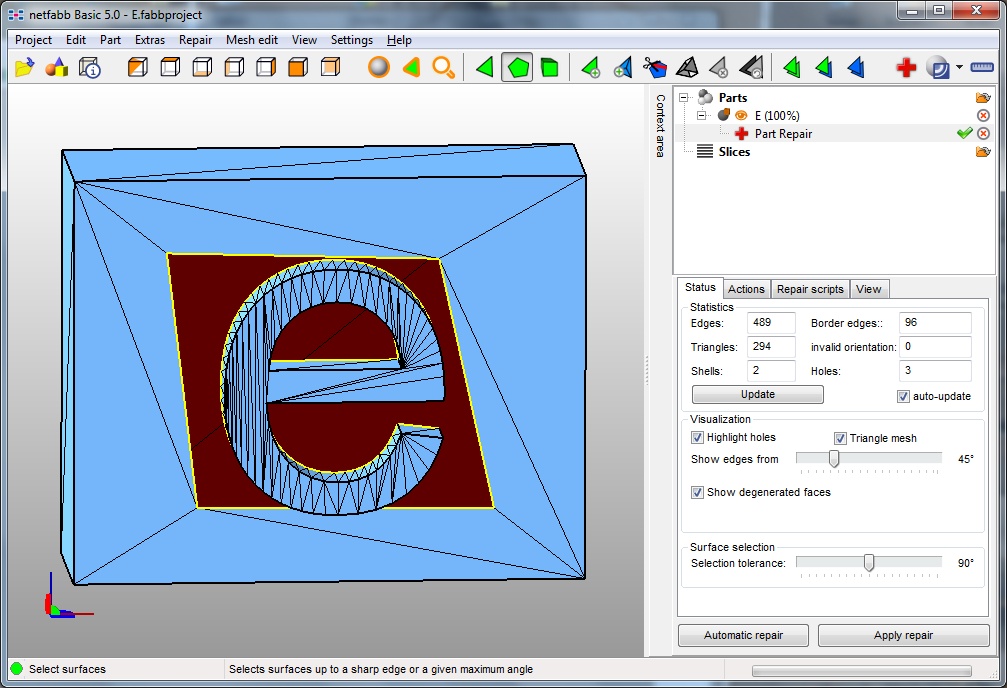

| Step 8 | That gives us a

hole in the main body to mate to, and the back of the "e" is also

now a hole. We can start closing up the holes. If you were

at this point to use the "Close All Holes" tool, it would simply put

us back with the two shells we started with. What we need to do is

give Netfabb some "hints" as to how it should close the holes. |

|

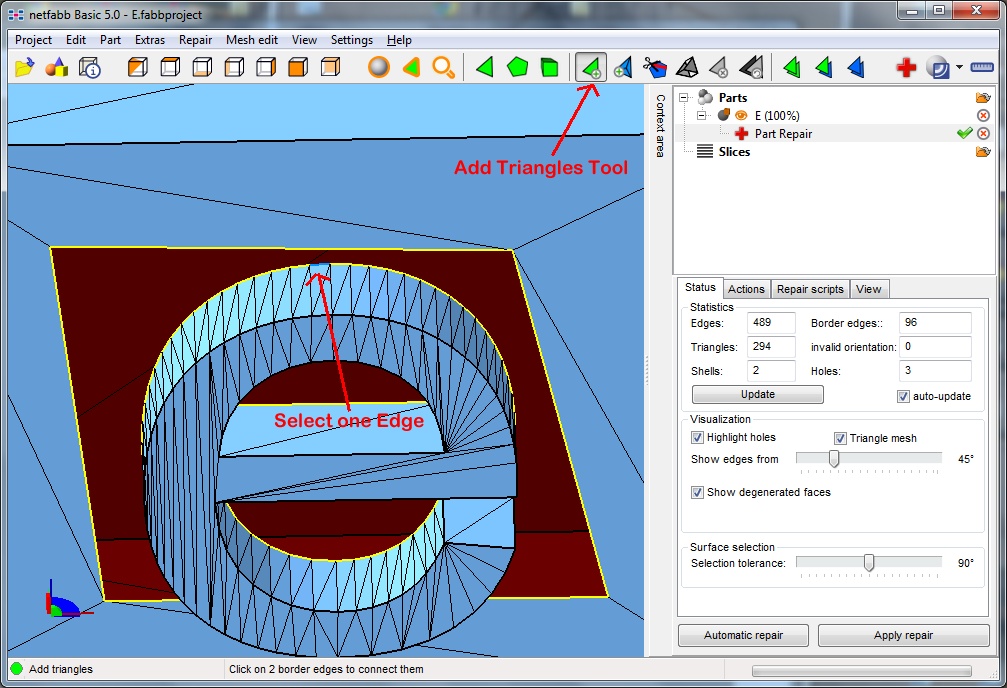

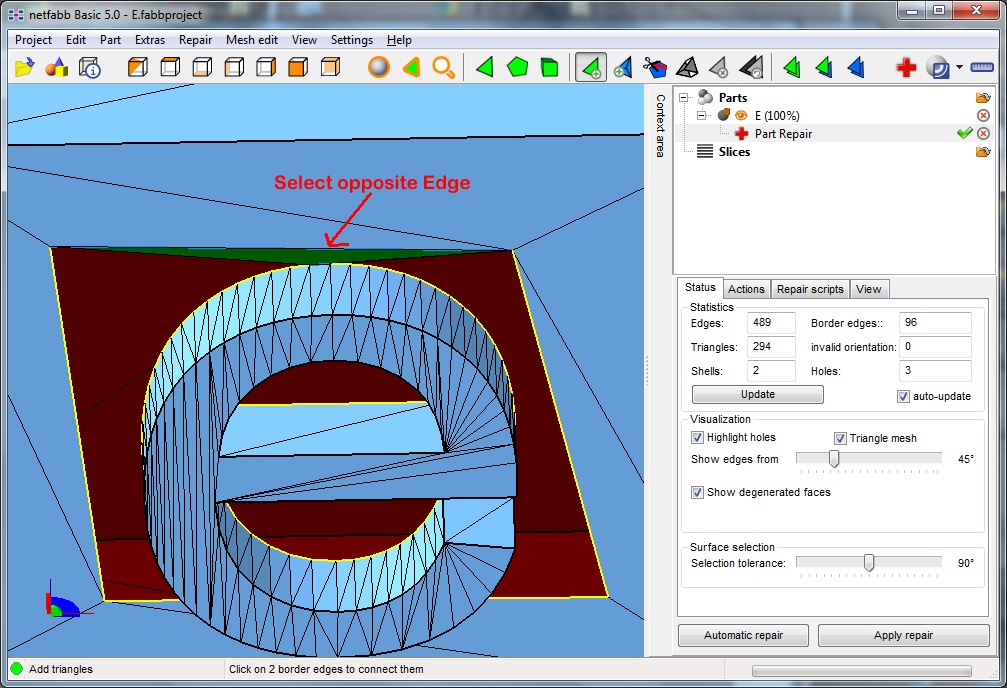

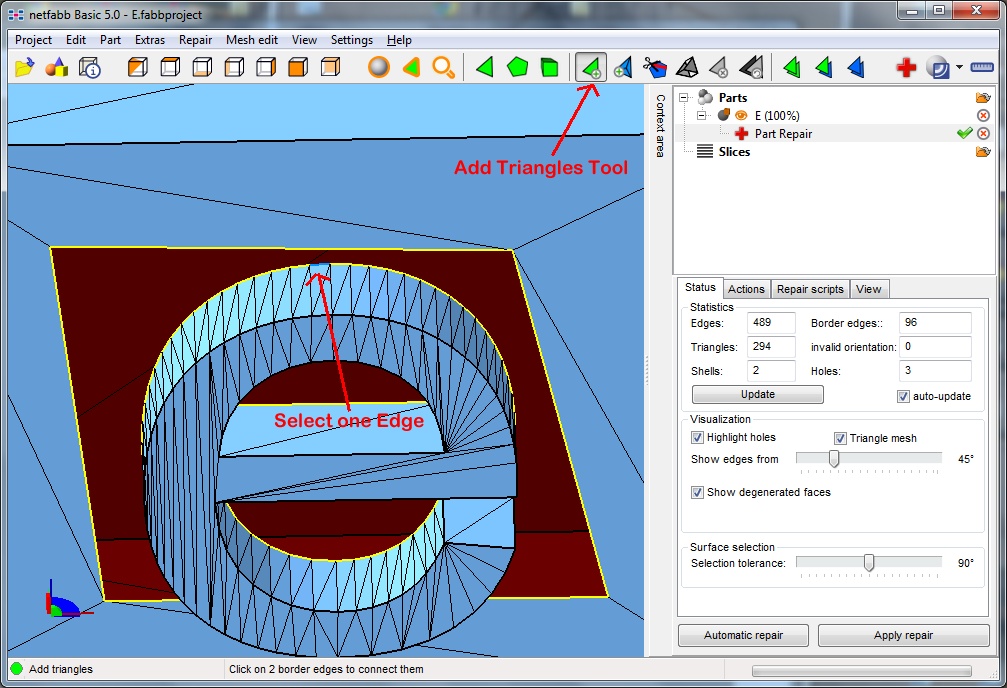

| Step 9 | Select the "Add

Triangles" tool. Then with the mouse click on one edge,

turning it blue. |

|

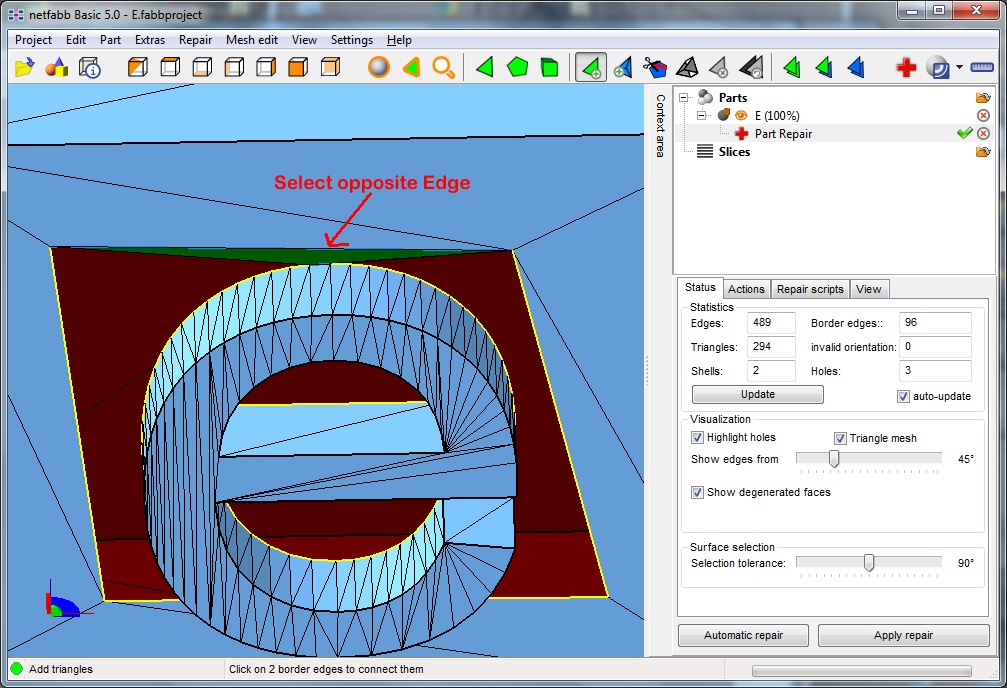

| Step 10 | Then, drag the

mouse to any other edge. You'll see that it fills in the gap with a

green triangle |

|

| Step 11 | If you then

click the mouse again, Netfabb will fill in the green area with

actual faces. |

|

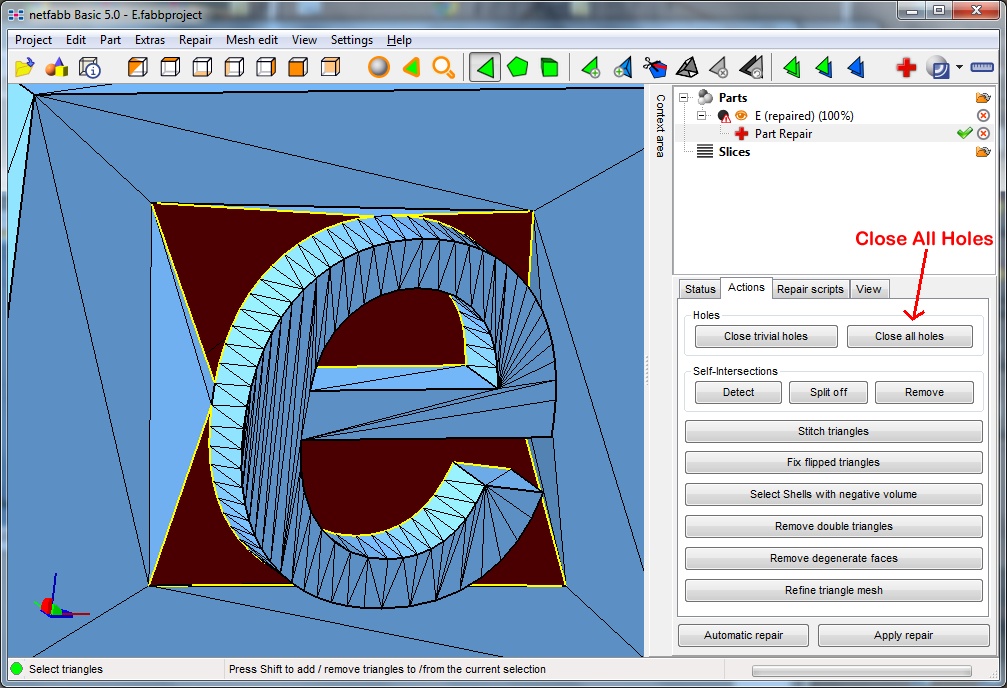

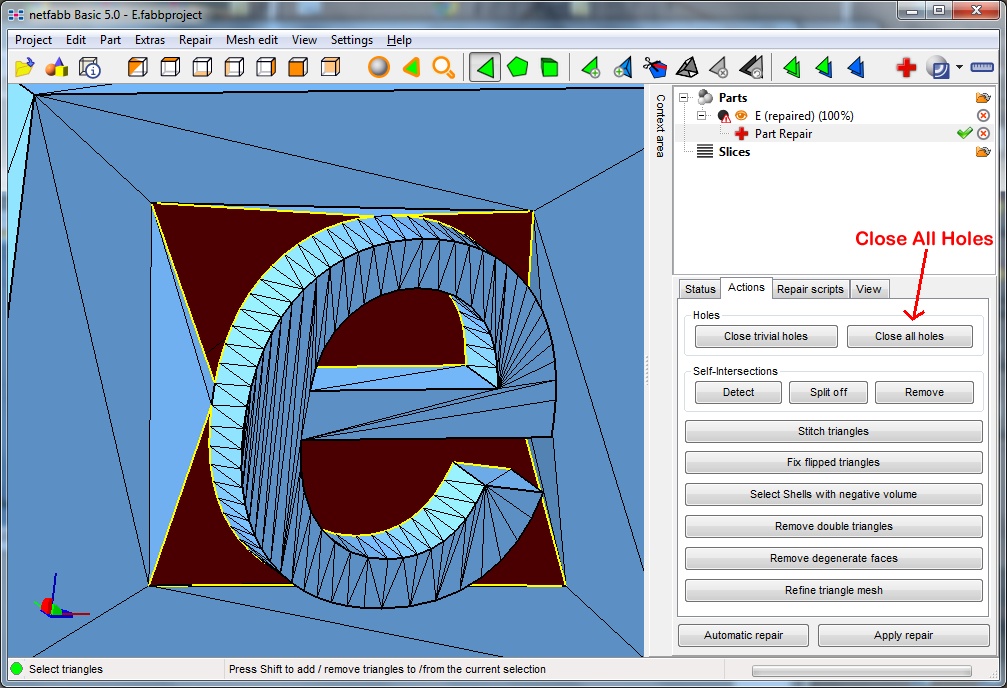

| Step 12 | Work your way

around the "e", selecting a number of faces to fill in manually -

you don't have to fill in everything, but you should fill in enough

so that it is not ambiguous where the automated repair tool should

fill in the gaps. Then click the "Close All Holes" button. |

|

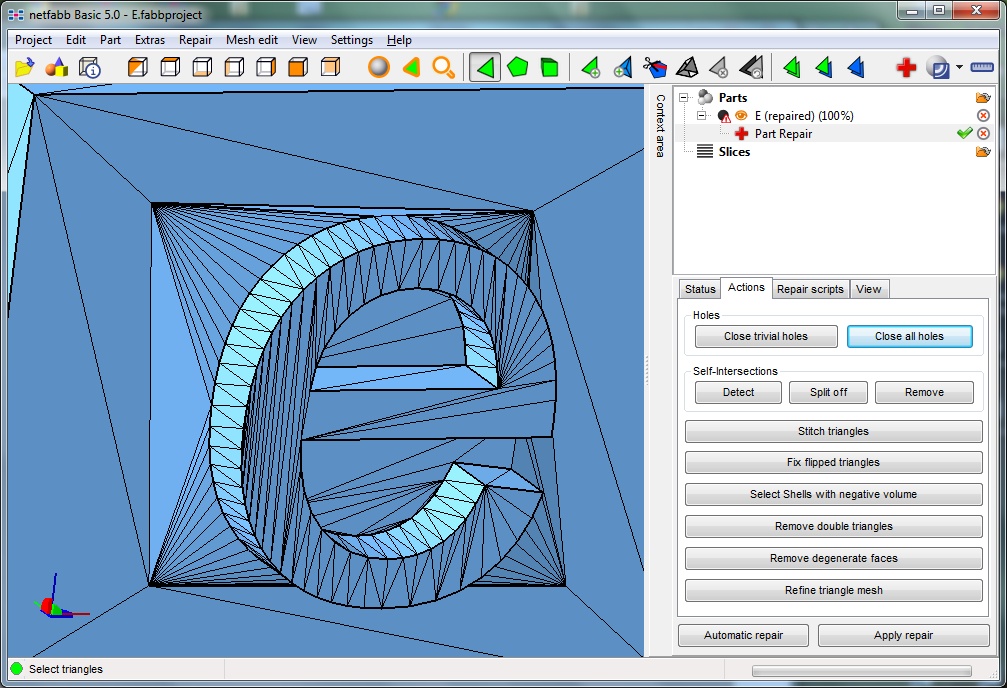

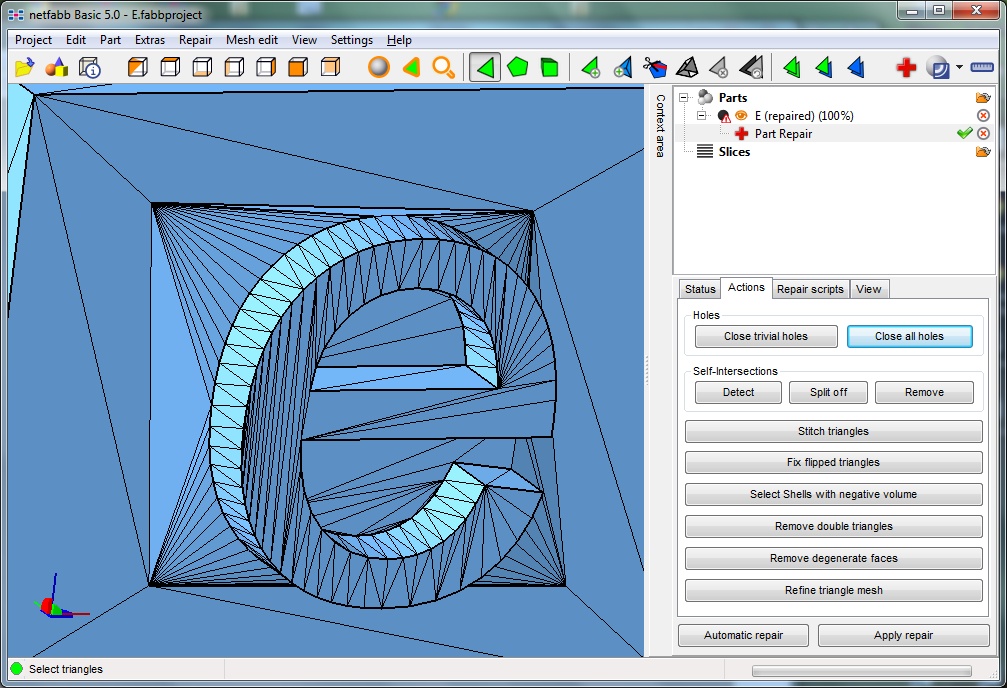

| Step 13 | Here's the

result. |

|

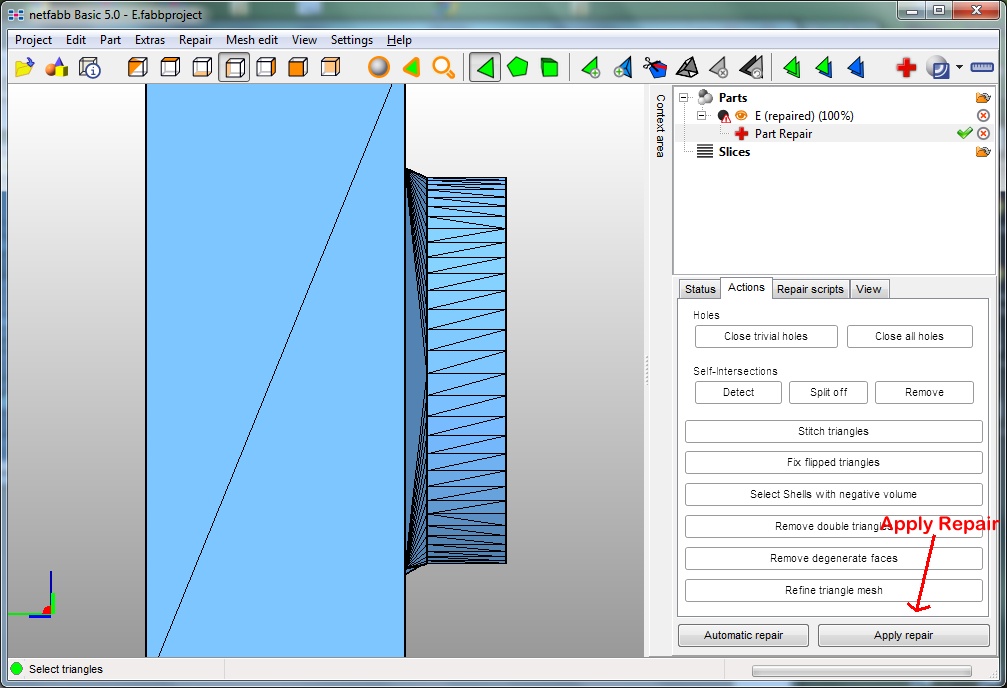

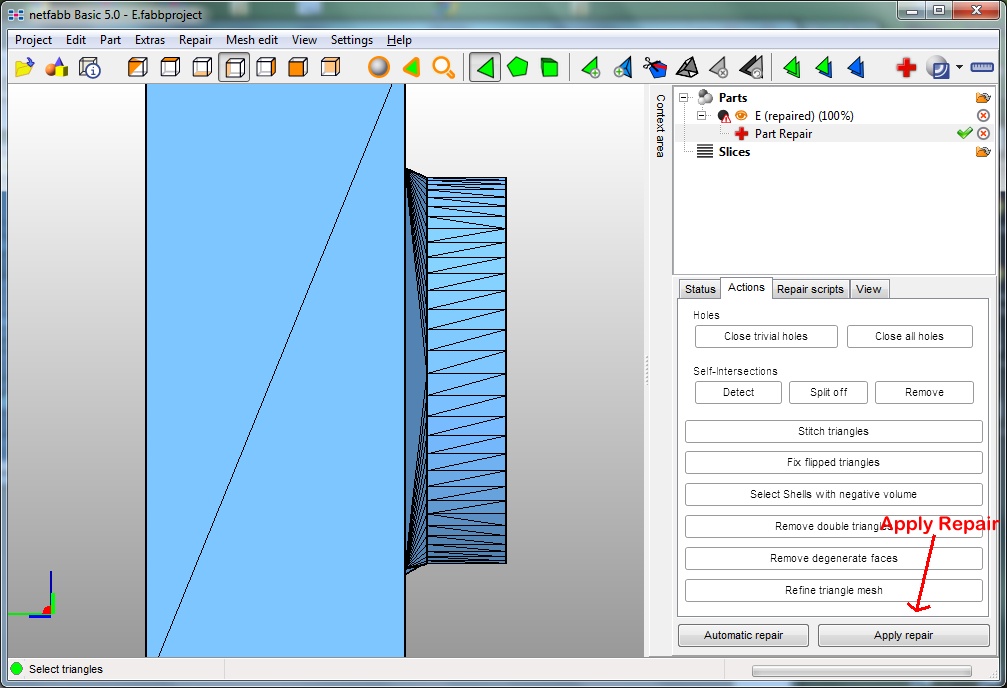

| Step 14 | And what it

looks like from a side view. Remember to click "Apply Repair" to

make your changes permanent. |

|

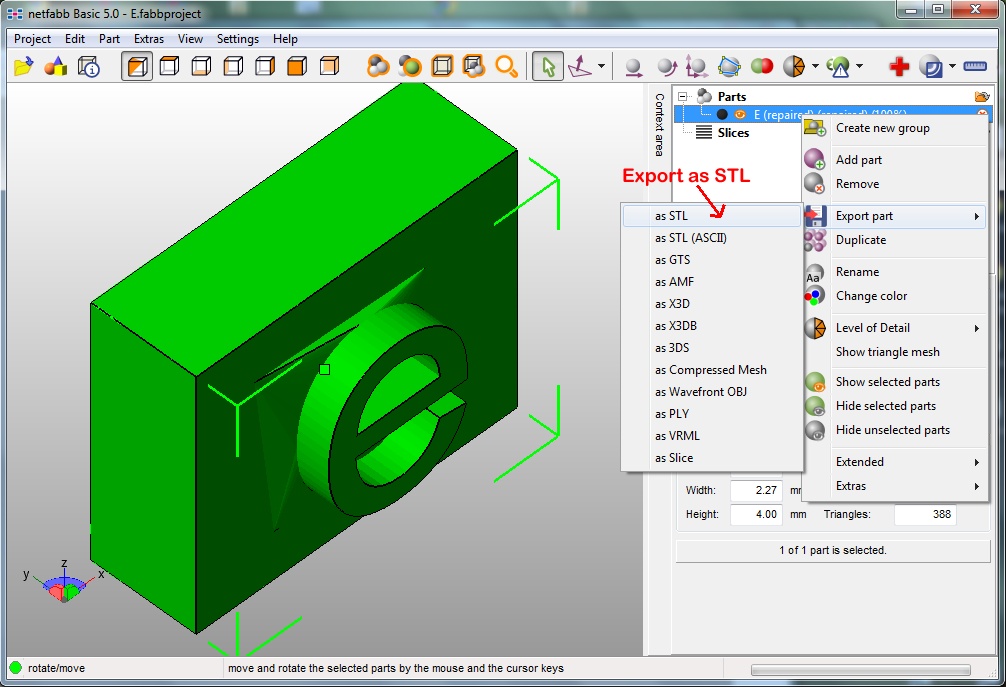

| Step 15 | Right click the

shell, then select Export and STL. Save the file.. upload it to

Shapeways.... |

|

| Step 16 | Order, paint and enjoy |

|