Can you enlarge or shrink this model to another size?

To disappoint you, the answer is "Yes!".

It takes only seconds to mathematically change the computer model from one size to another. But, you may not be happy with the results.

There are two factors at work here: Polygons and Price.

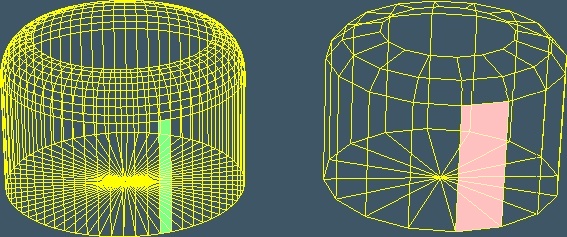

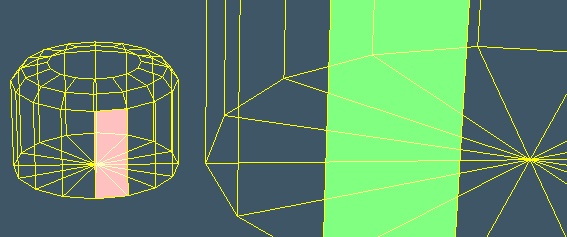

POLYGONS: Every computer model is made up of polygons, also known as facets. Often, they are simply triangles, but for the purposes of this discussion, I'm going to keep them as rectangles. Compare these two models:

.

The model on the left obviously is "finer" than the one on the right. The trouble is.. consider the width of the facet that I've highlighted in pink. It is four times as wide as the facet in green. When designing for a RP printer, you have to keep in mind the wall thickness limit, but you also need to consider the detail thickness limit.

When designing a model, you must keep the whole object above a certain thickness, but, you should also keep the facet size below the "detail limit". Let's say that the printer can print a detail at 0.2mm. If the Pink facet is 0.4mm and the green one is 0.1mm, then the pink one is going to show up as a flat spot on the model, and won't look curved. The green one will look just fine.

Why does this matter? Because.. when you take the model on the right and blow it up 4 times larger, you're then going to exaggerate how blocky it looks. I personally try to model at somewhere around 1/2 of the detail limit size, but that means my models won't necessarily still look good when enlarged. The only way you can overcome this is to split every polygon into smaller pieces, which sometimes is as complicated as drawing a whole new model.

Then what about scaling down? Going down presents a different problem. Again.. the wall thickness limit comes into play. If I have a segment of the model that was designed as 1mm thick, and I reduce the overall model by a factor of 4, then that segment is now 0.25mm thick, and it can't be printed on the printer. Here, again, it's a matter of having to re-design the model to account for the different thickness limits.

PRICE: Ah, the evil we must all deal with.. the wallet. The prices for printing these models is directly a function of how much plastic you use. If you use more plastic, the model becomes more expensive. If I have a model that uses 1 cubic centimeter of plastic and costs $3, then when I enlarge it four times.. it doesn't use 4 times as much plastic.. it uses 4x4x4 or SIXTY FOUR times as much plastic!!! That cute little $3 model now costs $192 !!!

The good news is that if I then re-design for the same wall thickness limit, you can shave off a lot of the cost. Let's say I have a flat rectangle at 2x5x1mm. That's one cubic centimeter of plastic. If I enlarge that 4x, but keep the same thickness, then it goes to 8x20x1mm or 16cm3.. "only" sixteen times more expensive. That's a lot better than sixty four, but it's still a whopping $48 compared to the original $3.

Let's consider a box that is 10x40x8 feet in size. If we remove the bottom, make it hollow, and then allow for the minimum wall thickness.. here's the prices for several different materials/scales:

| Scale | Volume | FUD | WD | FCS |

| Z | 2.66 | $3.39 | $8.22 | $6.63 |

| N | 6.91 | $5.77 | $11.39 | $7.32 |

| TT | 16.39 | $13.67 | $26.99 | $9.25 |

| HO | 42.85 | $35.74 | $35.92 | $12.30 |

| S | 256.05 | $213.57 | $140.60 | $48.16 |

Shapeways is doing a wonderful job at providing us with an outlet for our imaginations, and they have several material choices for us to select from. I am sure that over time, other materials will become available and hopefully at cheaper prices that may bring the costs of this process down to the point where it's economical for the larger models.

The other choice here is to print off one copy of a model and then use that as a master to make castings. Just remember.. if you do so with someone's model and then sell them, the designer should reap the benefits of his work.

Until such time, I (may) just stick to my little 1:220 world. Have you considered Z today?